4D Additive is a complete solution for preparing a print job.

A major advantage of the software is that the data to be printed is processed and optimized on the basis of B-Rep geometries, i.e. you do not move in the STL file format during print preparation.

This avoids a number of problems during file preparation for 3D printing, such as complex geometry repairs, excessive file sizes during transfer to the 3D printer and inconcistences in the geometry which prevent valid quality management.

All common 3D printing processes and printer types are supported.

The 3D printing software contains the functionalities:

- Import of CAD files and repair/healing

- Component analysis and direct modelling functions

- Positioning of the component / Multi-criteria Positioning

- Support for metal and plastic components

- 2D and 3D Nesting

- Face-based application of textures and fonts

- Slicing and export to printer

File import of all common formats via sophisticated interfaces

The import of CAD files to be printed takes place in the native data format. Further steps are based on data in B-Rep format. Thus the objects are described as solid models by their bounding surfaces instead of by tesselated surface elements.

- NX™

- CATIA®

- SOLIDWORKS®

- Creo®

- JT

- STL

- STEP

- ACIS®

Automated healing functions based on B-Rep geometries

The robust repair functions ensure optimum data quality of the converted data models and those optimized for 3D printing. These can be saved in amf, 3mf and STL formats.

The Healing feature for CAD models includes automatic gap closure and corrects overlapping elements, rotated surfaces and other geometric errors. In addition to automated healing, geometry errors can be detected in an interactive mode using filter functions and lifted in a matter of seconds using the clean-up functions. The repair functions ensure that high-quality, "waterproof" mesh models are sent to the printer.

Component analysis and direct modelling functions

The CAD geometry is analysed with special test profiles with regard to the various 3D printing processes. A wall thickness test can be used to analyze critical areas with a wall thickness that is too small for certain processes. In addition, surfaces, volumes and installation spaces are calculated. An analysis of massive zones as well as collision and internal gap dimension checks enable the identification of problem areas in order to align the component optimally for the pressure.

The CAD models can be processed on the basis of their B-Rep geometry using robust "direct modelling functions", which has significant advantages over the processing of tesselated models. Defeaturing and modifying critical geometry areas as well as merging surfaces can efficiently reduce complexity. Offset surfaces can be generated quickly. The models can be scaled differently along the three main axes by freely selectable scaling parameters. Shrinkage or distortion can thus be compensated.

Positioning of the component / Multi-criteria Positioning

First, the component can be quickly positioned on the building platform by hand. The full optimization potential is achieved with intelligent criterion-based positioning aids from 4D Additive.

The database stores the common machine types and their installation spaces, as well as the associated materials and costs. Process-specific restrictions are also stored, e.g. for SLS or FDM, with regard to the best positioning according to the surface quality of a selected surface.

The multi-criteria positioning helps to optimize costs, construction time, scope of support and quality. It uses intelligent algorithms to automatically position the component according to a given weighting of the criteria.

Support for metal and plastic components

Support structures can be created in 4D Additive for the preparation of metal printing components and for the use of plastic printing processes that require support.

In addition to automatically generated stable support structures, semi-automated tree and lattice geometries can be generated for lightweight construction and material savings. The Direct Modelling functions ensure maximum freedom when editing the support structures and positioning on the component. Various patterns can be selected for filling the lattice areas, such as honeycomb, octet or center point.

2D and 3D nesting

2D and 3D nesting functions ensure fast, easy filling and optimum use of the installation space. You can select the components to be manufactured (as well as their number), the minimum distance to each other, the orientation and areas that should not be occupied.

Afterwards, the build space is automatically filled using intelligent algorithms and collision control, so that an optimized number of components can be accommodated on the platform. The optimized build space can be saved as a print job.

Textures and colors: Texture generation based on exact geometry

The assignment of textures and colours to the surface of the components to be printed is based on the exact (B-Rep) geometry.

Thus the transitions at the surfaces can be defined very simply and exactly. Especially with high-resolution printing processes, very beautiful surface textures are created for visible components or functional surface structures, e.g. for the realization of defined sliding properties. More than 5 thousand predefined textures are already available in 4D Additive's texture library.

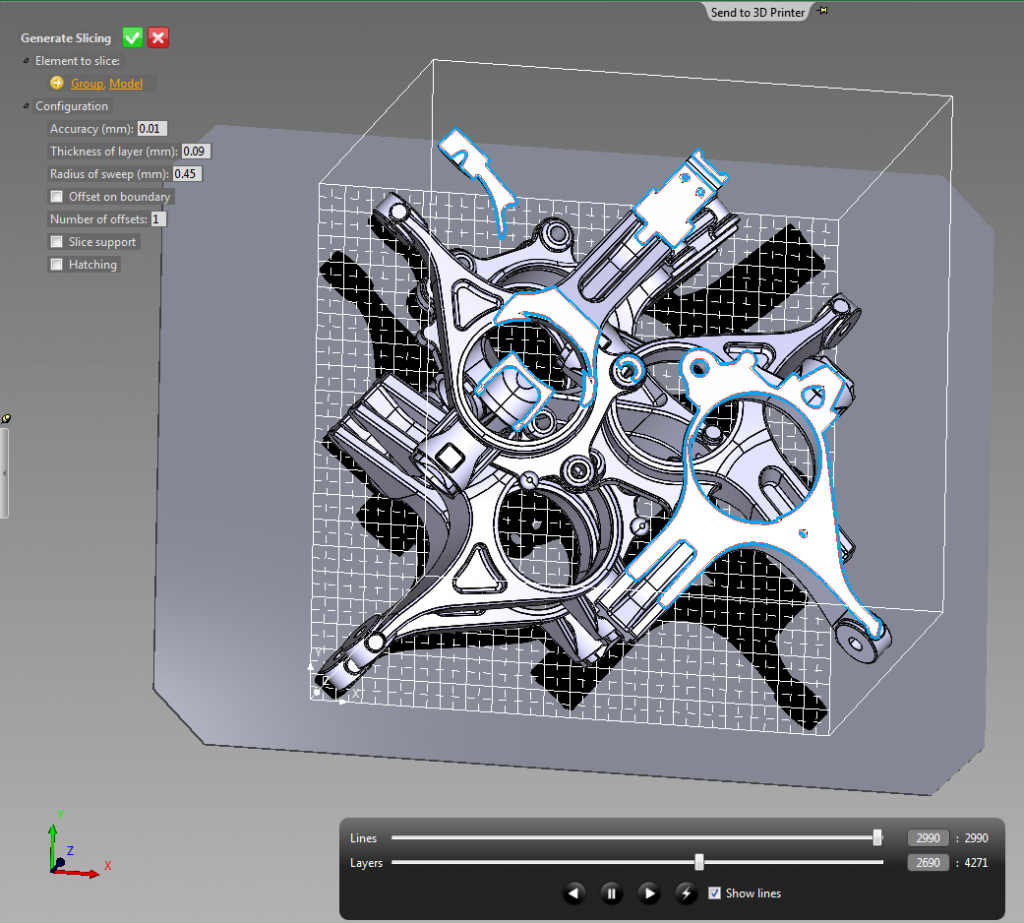

Slicing and export to the printer

4D Additive includes a robust slicer for the prepared B-Rep geometries. The slices can be exported in the formats ABF, CLF, CLI, CLS, G-Code (G1 and G2/ G3!), SLC, SLI, SLM, SSL or USF.

The components of the created print job can also be exported to the 3D printer after tessellation in the formats 3mf, AMF or STL.

LET´S CONNECT EACH OTHER

SUBSCRIBE OUR NEWSLETTER

Get relevant information and release notes

4D Additive Newsletter

Signup for news about 4D Additive - the 3D print preparation tool!

Thank you!

You have successfully joined our subscriber list.

Would you like to get to know the software in action? Contact us for an on-site appointment or a video conference.

4D Additive

4D Additive- A Software solution from CoreTechnologie GmbH distributed by enter2net.com AG